WHY CHOOSE US

Gitani Stone’s Jason Gittany attributes the company’s success to innovation and an R&D program that delivers unique products of the highest quality from their state-of-the-art factory located in Seven Hills, NSW.

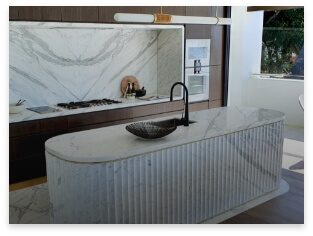

Luxuryis our pride and expertise

All work is carried out in-house at the state-of-the-art factory in Seven Hills, where we are capable of providing any finish imaginable, including laminating glass on stone, antiquating marble or granite, hand chiseling, and bending of Caesarstone. Our finished products include custom-made benchtops, bookmatched flooring and wall panels, fireplaces, and water features, to name a few.

Creating a timeless look is possible with the right materials and correct advice from Gitani Stone. Our modern facilities and experienced staff provide the right ingredients to make it happen.

OUR PROCESS

REPUTABLE QUARRIES

CUTTING BLOCKS

INTO SLABS

FOR EASY VIEWING

& SELECTION

WHICH IS PRECISELY CUT

CALIBRATED

SHAPED TO ANY DESIGN

AND INSTALLED WITH PRIDE

OPENING HOURS

MONDAY TO FRIDAY

8.00AM – 4.00PM

SATURDAYS

BY APPOINTMENT ONLY

9.00AM - 1.00PM